Products

- Plating Thickness

- Painting Thickness

Painting Thickness

- Laboratory Supplies

Laboratory Supplies

- Electrolyte Solution

Electrolyte Solution

- Calibration Standards

Calibration Standards

Multifunction Tester

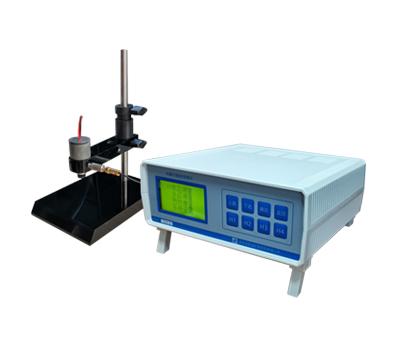

▉ Ideal for measuring the thickness of the electroplating layer

▉ The instrument works according to the ISO2177 standard Coulomb method

▉ Simultaneous display of thickness and potential values during testing

▉ Small size tends to be portable and more powerful

▉ Simple mode with 4 control keys to complete all test tasks

▉ 4 hot keys to easily define common coating test procedures

产品详情

▉ Electrolytic Thickness Tester for Electroplating Layer Quality Control

The electrolytic (coulometric) method is a simple and easy-to-use electrochemical analysis

method for determining the thickness of metal coatings.

Many common single-layer and multi-layer coatings can be accurately measured by the

DJH series electrolytic thickness Testers.

▉ Application Scenarios

The electrolytic thickness tester is an ideal instrument for measuring various single-metal

and multi-metal coatings on metal substrates (such as steel, copper and copper alloys,

die-cast zinc, aluminum, etc.) or non-metal substrates (such as plastics, neodymium iron

boron, ceramics, etc.).

Widely used in the following industries: automotive, motorcycle, aerospace and marine,

sports equipment, bicycle, lighting, electronics and electrical appliances, high and low

voltage switches, sanitary ware, plastic electroplating, standard parts, hardware,

neodymium iron boron, security products, cables, kitchenware, quality supervision

departments, testing and research institutions.

The electrolytic thickness tester offers high cost performance and can accurately

replace expensive X-ray fluorescence thickness gauges, allowing you to conveniently

measure coating thickness using the electrolytic method. It is suitable for a wide

range of coating/substrate combinations, providing maximum flexibility in the

quality control of electroplated coatings.

Usually, when the total thickness of single-layer or multi-layer coatings reaches a

certain level, the non-destructive measurement of coatings by X-ray fluorescence

reaches its limit, which is when the DJH series electrolytic thickness testers play

their unique role.

Due to its electrolytic measurement method, it becomes the only testing instrument

capable of testing the thickness of multi-layer nickel and potential difference (STEP

test)*. (DJH-G multi-layer nickel potential difference tester is required for selection.)

Based on the coulometric method of ISO2177 standard, the metal or non-metal

coatings with precisely defined areas are electrolyzed using corresponding

electrolytes and currents, which is equivalent to the reverse process of electroplating.

The completion of coating electrolysis is detected by changes in the voltage of the

electrolytic cell. Since the test current and test area remain unchanged during the

test, the coating thickness is directly proportional to the electrolysis time.

▉ 独特之处

性能超卓

独创的8个多功能按键

可从70多个镀层/基材组合中自定义

4个常用镀层测试按键

众多功能只需4个功能键即可轻松实现

交互式液晶屏

独有的仪器参数及状态显示屏

所有功能及仪器参数设置都在液晶屏

以层级菜单形式列示

各种参数及测试状态一目了然

预置测试镀层

开创性镀层/基材测试程序快捷键

仪器可预置

4种常用镀层/基材组合程序快捷按键

并可以自行修改重定义

对于复合多镀层测试其优势更为明显

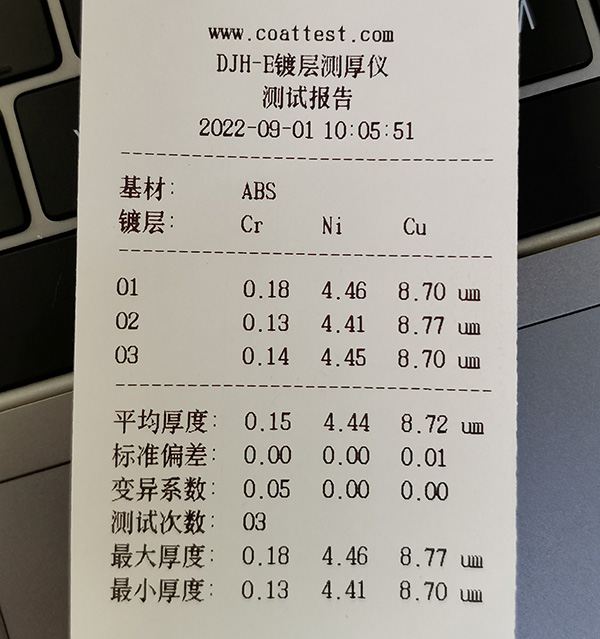

统计打印

更佳的数据统计打印体验

不仅仅是简单的数据打印

对于复合多镀层(如铬/镍/铜)

测试多组数据后

可以将多次测试数据

并列打印在一张统计报告上

包括如下信息:

平均值、最大值、最小值、标准偏差、测试次数、时间等

暂停测试

独有的多镀层任意层暂停测量

对于厚的镀层(如硬铬)

每20um需要更换一次电解液

此功能可在不终止测量的情况下进行

此外

特别是复合多镀层测试过程中

可保持当前镀层的测试状态不会退出

继续测试而不影响数据的连贯性

重启测试

特别适合多镀层任意层重启测量

在测试整个过程中

特别是测试中间镀层

如果发现测试错误可及时终止

并重新启动当前镀层的测试程序

不用整个退出测试程序

错误预警

通过电位可判断错误原因

在测试过程中难免出现一些人为错误

这样会影响测试准确性

通过对测试过程中电位的观察

可及时发现并排除错误

恒压底座

独有的恒压定位固定装置

在测试过程中由于装夹样品时

施加在被测点上的压力大小不同

会影响测试的一致性

通过恒压底座即可消除此影响

附带的V型槽便于柱状样品定位

▉ 技术参数

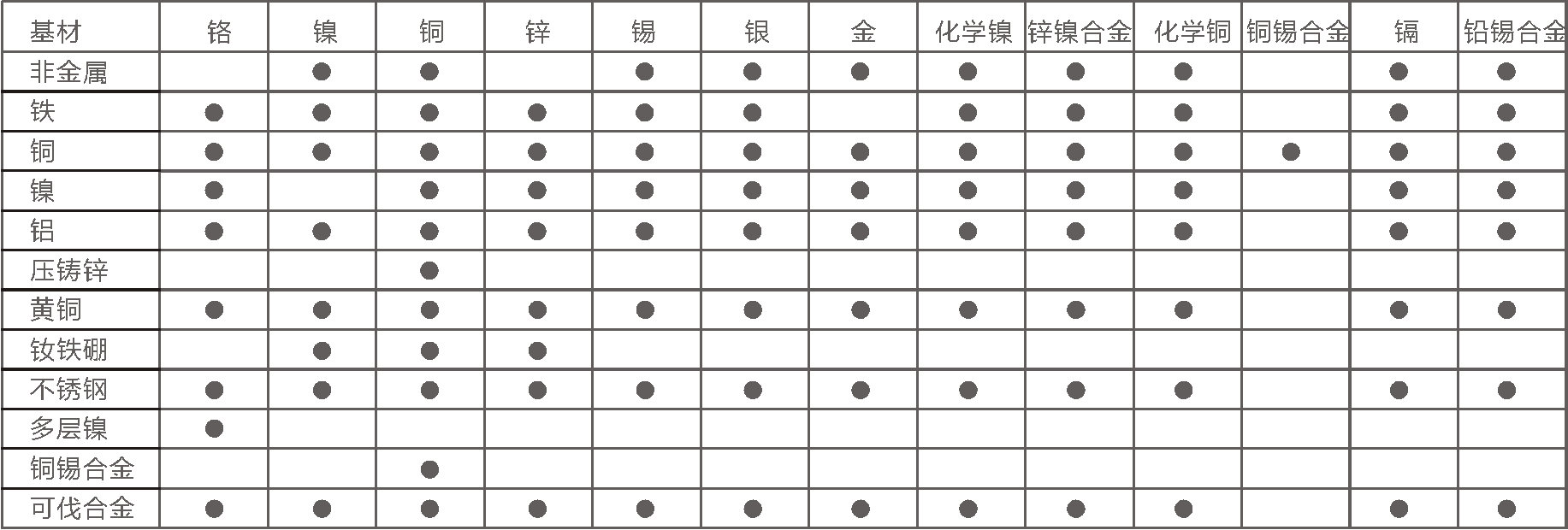

| 测量镀种 | 单金属镀层 | 复合多镀层 | 合金镀层 | 多层镍 |

| Cr、Ni、Cu、Zn、Sn、Ag、 Au、Cd、Co、Pb 等10多种 | Cr/Ni/Cu 等10多种 | NiP、ZnNi、SZn、SPb 等约10种 | 需选用DJH-G多层镍电位差测试仪 | |

| 镀层基材 | 金属 | 非金属 | ||

| 如钢铁、铜及铜合金、 压铸锌、铝等 | 如塑胶、钕铁硼、陶瓷等 | |||

| 测量范围 | 0.03~300μm | |||

| 最佳使用范围 0.03~50um,超过 50um,误差会逐渐变大 | ||||

分 辨 率 | 0.01um | |||

| 重 现 性 | ≤5% | |||

| 示值误差 | ≤10% | |||

| 电位范围 | 0~3000mv | |||

| 电位精度 | 0.01mv | |||

| 测头尺寸 | 标配:φ2.4、φ1.7(单位:mm) 可另购:φ1.2、φ1.0、φ0.8(单位:mm) | |||

| 线材测试 | 需选用CTM208线材测厚仪 | |||

| 测 试 架 | 标配:STD07 测试架 | |||

| 校 准 | 厂家校准 具备校准片情况下可自行对单一镀层校准或统一校准 | |||

| 终止测量 | 自动判断 | |||

| 单机使用 | 只可单机使用。如需连接电脑使用,选用DJH-G多层镍电位差测试仪 | |||

| 打 印 | 嵌入式热敏打印机打印测试结果。如需用激光或喷墨打印机打印 A4 幅面测试结果,选用DJH-G多层镍电位差测试仪 | |||

| 打印内容 | 镀种、单次测量值、平均值、最大值、最小值、标准偏差、变异系数、时间 | |||

| 显示方式 | 126*64 点阵液晶显示屏 | |||

| 测试热键 | 可自定义4个单镀层或多镀层/基体组合选择热键 | |||

| 暂停测试 | 对于厚的镀层,可以随时暂停,更换电解液后再继续测试 | |||

| 电 源 | 交流 220V,可定制交流 110V | |||

| 主机尺寸 | 200*255*161(mm) | |||

▉ 常规镀层应用程序

▉ 演示视频